Temperature for Concrete Curing

For concrete to achieve full strength, it is believed that the standard temperature for curing is 55°F. Weather condition does not determine this standard temperature.

How The Hoover Dam Curing Was Accomplished

One of the largest dam worldwide after it was completed was the hoover dam. On June 6, 1993, was an unforgettable day for engineers on the site of the dam as they start the first concrete pour. The dam took the pattern of individual columns instead of single block concrete. Single block concrete pattern would have taken a century to cool to ambient temperature because of the heat produced during curing. It stood five-foot lifts in a trapezoidal column shape. Engineers built the dam in such a way that it will allow heat produced by the curing to be dispersed. Had it been the dam was built in a single pour, the stress on the concrete would have caused a crack in the dam.

The team of experts faced so many challenges but that of the heat and dryness of Nevada was a major challenge. After the pouring of concrete, river water was used to improvise in cooling coils of 1 thin-walled steel pipes. Another set of cooling water from a refrigerator plant was applied on the lower cofferdam to circulate the concrete via the coils in other to finish the cooling effect.

Appropriate Temperature For Concrete Curing

The following shows temperature best for concrete curing: Two concrete curing process 120°F and 55°F both process at the same weather condition.

Day 1 – 120°F – concrete cured looks strong.

55°F – concrete cured is weak.

Day 7 – 120°F – concrete cured has no more strength for curing.

55°F – concrete cured still has the strength for curing.

Day 28 – 120°F – concrete cured starts getting weak

55°F – concrete cured becomes stronger.

28 to 365 days – concrete cured under 55°F is considered stronger than 120°F concrete

The Art Of Concrete Curing

In every project or job given, people tend to use quick and fast methods of finishing the job within a short period of time. However, concrete if cured quickly or under severe curing temperature will at the end result to a weak concrete. Hence it is appropriate for concrete to cure at an average temperature of 32°F – 50°F with the right amount of moisture. Although concrete curing is slow at this temperature nevertheless it will attain its full strength. In no case should the temperature of concrete exceed 90°F or dry out during curing process no matter the weather condition, this, in the long run, will result in flaking.

Conclusion

This practically states that, as long as curing is constant and never stops, concrete cured at 55°F from day 1 to day 28 will ultimately reach its full concrete strength.

Is the temperature too cold?

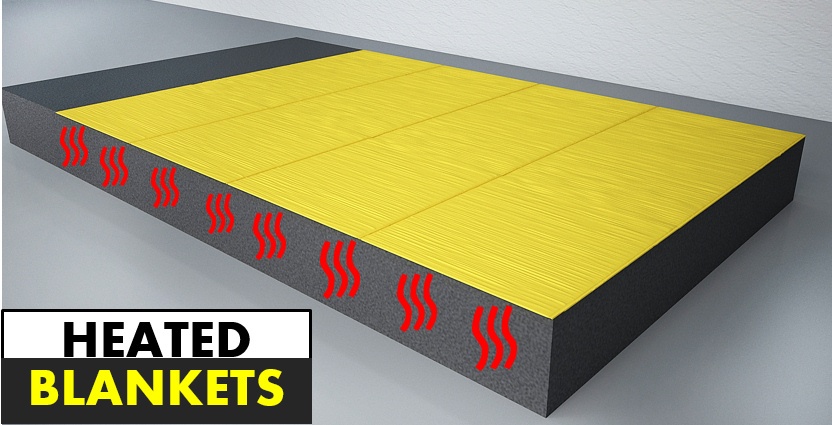

Worry less during winter. Electric Curing Blankets provide a way of curing concrete with ease and effectiveness in cold weather condition. With the use of electric curing blanket for curing process, production increases through consistent curing.

FEATURES

- Cures more or less three times faster than conventional or insulated blankets.

- Generate concreting strength of about 3,925 psi within 72 hours in cold weather.

- Maintain moisture throughout the hydrating process.

- Simply installed and removed.

- Avert a freeze cycle.

- Melts ground and frost from the previous job before pouring in a new project.

- Increase profit.

- Maintain ACI compliance for cold weather condition concreting.