OVERVIEW

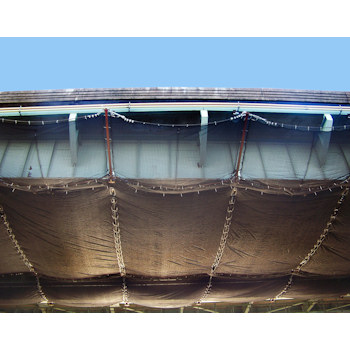

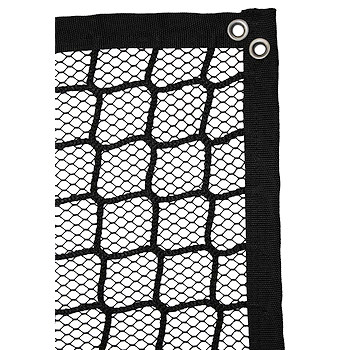

ALCO construction debris netting provides complete debris containment with a combination of a structural net and an optional fabric debris liner. This all-in-one solution is designed for protecting public areas and pedestrians from construction debris, as well as catching smaller items such as dust and dropped tools. This is the heaviest duty construction net on the market.

Flexibility That Meets Code

Nets can be linked together, wrapped, or suspended, depending on your specific needs. Can be used for vertical or horizontal containment. Also available in single or stacked configurations. Complies with OSHA regulations for debris net installations and meets CPAI-84, Section 6, Tent Walls and Tops. Also meets conformity standard ANSI A10.37 for Debris Net Systems for Construction and Demolition. Optional hardware is available for a turnkey solution. Just ask our experienced staff.

Please note that hardware is not included on the shopping pages. If hardware is required, please use our custom quote page so an ALCO technician can quote the right hardware for your specific project. With custom quotes we can make sure you are using the correct debris nets and hardware so that its correct and safe!

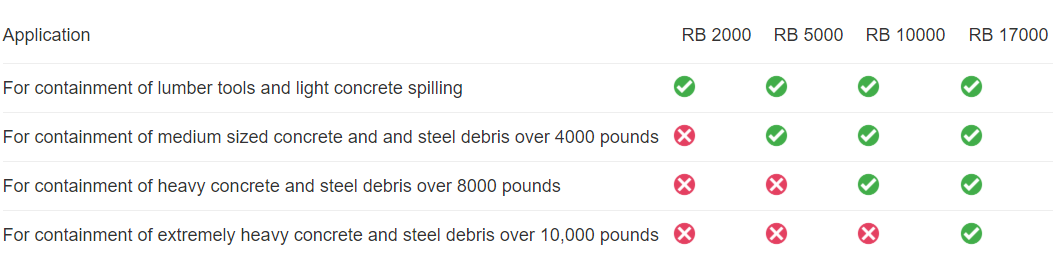

Industrial Drop Netting Models

Model: RB-2000

Weight Rating: 2000 Pounds

Ideal For: For containment of lumber tools and light concrete spilling

Mesh Size: 2″

Material: 1250 High Tenacity Polypropylene knotless netting

Grommets: Every 2 feet on center

Price: $

Model: RB-5000

Weight Rating: 5000 Pounds

Ideal For: For containment of heavy concrete and steel debris

Mesh Size: 2.5″

Material: 820 High Tenacity Polypropylene knotless netting

Grommets: Every 2 feet on center

Price: $$

Model: RB-10000

Weight Rating: 10,000 Pounds

Ideal For: For containment of heavy concrete and steel debris

Mesh Size: 2.5″

Material: 820 High Tenacity Polypropylene knotless netting

Grommets: Every 2 feet on center

Price: $$$

Need help deciding?

Drop Netting - Heavy Duty | FAQ

Can you install safety nets to handrails?

Safety nets must never be attached to handrails unless they have been designed to take a minimum 6kN load at 45 degrees to the vertical.

When are safety nets required?

Safety nets shall be provided when workplaces are more than 25 feet above the ground or water surface, or other surfaces where the use of ladders, scaffolds, catch platforms, temporary floors, safety lines, or safety belts is impractical.

How often should safety nets be tested?

All safety nets used for fall arrest must be subjected to an annual test of the energy absorption capacity of the net. When new, a safety net will normally be supplied with three test meshes loosely attached to the safety net. At no more than 12 month periods a test mesh will be taken off and tested. Where the test mesh exceeds the minimum energy absorption capacity stated by the manufacturer, then the nets may remain in service for a further period not exceeding 12 months. Where the energy absorption capacity falls below the level stated by the manufacturer, then the net must be removed from service and destroyed.

Are safety nets suitable on my project?

When thinking about the netting, consider how and where they will be attached below the work area. Safety netting is most suited to steel or timber framed buildings where the nets can easily be attached.

What type of attachment is appropriate for safety nets?

Forged steel safety hooks or shackles shall be used to fasten the net to its supports.

How far should safety nets extend?

Nets shall extend 8 feet beyond the edge of the work surface where employees are exposed and shall be installed as close under the work surface as practical but in no case more than 25 feet below such work surface. Nets shall be hung with sufficient clearance to prevent user’s contact with the surfaces or structures below. Such clearances shall be determined by impact load testing.

What is the largest acceptable mesh size for safety nets?

The mesh size of nets shall not exceed 6 inches by 6 inches. All new nets shall meet accepted performance standards of 17,500 foot-pounds minimum impact resistance as determined and certified by the manufacturers, and shall bear a label of proof test. Edge ropes shall provide a minimum breaking strength of 5,000 pounds.