OVERVIEW

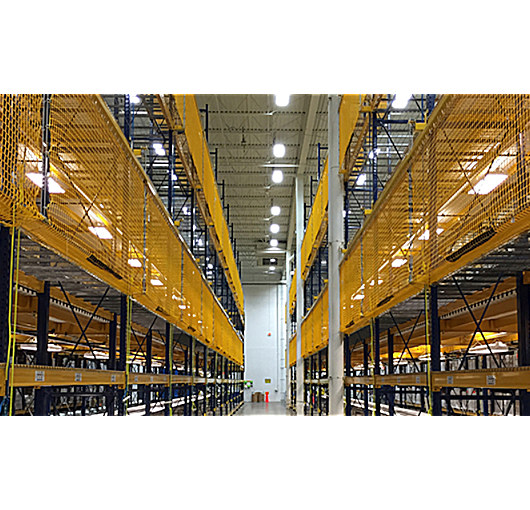

ALCO safety netting systems for pallet racks are used to protect stock from falling. Vertical applications include back of rack protection on single rows, reserve storage protection in picking applications, and in flue spaces for back-to-back racks. Horizontal applications include netting under pallet flow lanes in pick modules and under carton flow systems to catch boxes.

Rack Net Advantages

Our rack guard can be installed vertically or horizontally; below conveyors, above sorting lines, on the sides, rear or front of racks – anywhere you need custom nets to reduce product loss and keep people safe.

Use ALCO safety custom nets on “gravity flow” racks where employees are working and the risk of injury is higher from excess or reserve stock stored above in standard or push back racks.

ALCO industrial nets can be used in “flue” spaces between back-to-back racks. Many customers experience product loss when cartons fall down into the flue space. In most cases it is labor-intensive to clean up fallen cartons. ALCO custom nets may be a good solution from a maintenance point of view.

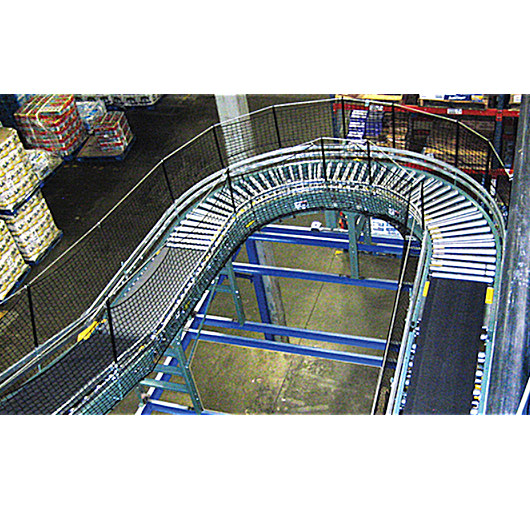

Conveyor Guards and Conveyor Belt Safety

Perfect for underneath and around virtually every type of conveyor application including belt, roller and overhead systems. Our custom guards are excellent choices for monorail and tilt tray sortation systems as well as garment or “slick-rail” conveyors in distribution and laundry applications. The lightweight netting used in conveyor guard systems will protect workers below and offer a “softcatch” reducing product damage possible with metal guards.