On Safely Handling Tarps

Making use of a tarp at work is bothersome and taxing. It’s also a health hazard too. Accidental slips and handling accidents can consequently lead to disabling, and even fatal, undesirable injuries. But your workers must use tarps daily to protect themselves, the work’s assets, and company materials. One can reduce chances of tarp-related accidents by implementing programs to train staff on proper handling practices of tarps.

Tarp-Handling and its Hazards

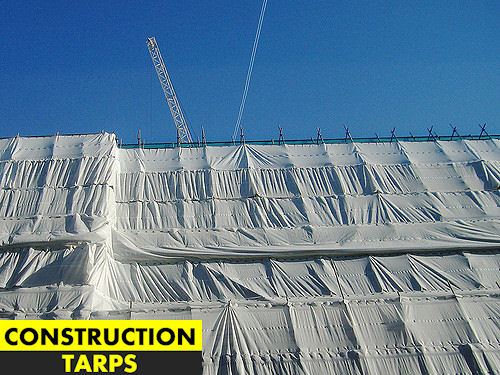

Workers utilize different tarps depending on purpose on a given job site, and each kind of tarp has its own set of hazards. Water-resistant ones are heavy, and are used to cover large structural openings. These heavy ones are hard to maneuver and always best moved around with mechanical equipment, such as cranes. But though more convenient, these mechanical aids are not always available, and workers are left with one choice, doing everything by hand. This puts workers in situations where manual labor is the only option, and potentially gives risk of injury.

There are tarps that are made using lighter materials, conveniently dubbed lightweight tarps. These lightweight tarps, while easier to manage, still pose hazards. Materials left from its fireproofing process significantly increase tarp weight, making removal challenging, taxing and tough. Insulated tarps, designed to cover curing concrete still are hazardous to work staff, as workers bend to pull the tarps from foot level, possibly leading to overexertion of the body. Most materials tarps are made from are highly combustible, and can lead to fire accidents when used within proximity of welding equipment, or those ones that produce sparks and fire.

All tarps, regardless of kind, are prone to changes of wind, as it gusts of wind can violently pick it up from its place. It’s always crucial that that safety measures are always in place – making sure the tarp is secured and staff are properly trained.

Work Site Hazards Prevention

Preventing work hazards is always key to unwanted accidents, injury and project delays. Let’s read through some tips to help make your work environment and your staff safer:

• Make use of mechanical equipment whenever possible to help eliminate manual labor and injury.

• Have a contingency plan readily available should mechanical aids be not available.

• Study the kinds of tarps. Use the tarp fit for your work environment

• Always have perimeter protection for tarp installation and removal. Should perimeter protection not be possible, see to it that all workers have safety equipment.

• Assure proper assembly of all scaffold frame couplings to resist the influence of wind and weather.

• Position and secure tarps properly on trucks, load cargo properly to minimize chances of tearing.

Hazards for Drivers

Moving construction cargo to work sites are also high risk for truck drivers, due to possible injuries from overexertion, and and falls from machinery. Although typically, mechanical aids are mostly available at work sites, drivers must remove large, heavy protective tarps from loads manually by themselves upon delivery. In some cases, drivers have to disengage tarps with no steady footholds.

What to do to for prevention:

• Pulling tarps from below the shoulder towards the torso is more effective and gives less strain compared to a downward pull with hands above shoulder height.

• A hard pull is better than pulling the tarp slowly.

• Securing loads in plastic leashes forces to a tolerable extent.

• Rather than doing tasks individually, attending to tarps in groups greatly reduces manual labor and energy exerted.

Implementation of safety measures that need to be met for further safety in manually moving tarp covers should mechanical aid be not available:

• When a forklift or a crane is not available, get help from other workers and plan the lift. Keep the load close to the body, avoid twisting, and lift together.

• Avoid strains and falls while pulling tarp off a load:

• Seek help from other staff to lessen strain and plan the lift.

• Know the distance and possible obstacles the workers will be facing/exposed to.

• Take close attention to proper footholds and elements the tarp and the workers will be exposed to while the tarp and workers are on the move.

• Have a firm grip on the tarp and not just the ropes, which can slip or break.

• Spread feet for balance.

• Utilize body weight to pull the tarp.

• Pull tarp facing it, to watch its movement.

• Reduce arm and shoulder strain when folding tarps:

• Put down tarp flat on a surface to check for holes or tripping hazards.